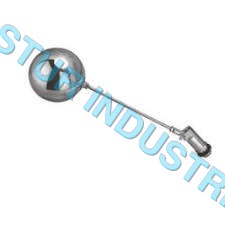

ss316 float valves

Price 200 INR/ Piece

ss316 float valves Specification

- Application

- Water Tanks, Chemical Tanks, Industrial Applications

- Size

- Customizable

- Structure

- Valve Body with Float Arm

- Connection

- Threaded (BSP/NPT)

- Sealing

- PTFE or Viton Gasket

- Product Type

- Float Valve

- Material

- Stainless Steel 316 (SS316)

- Power Mode

- Manual

- Pressure

- Up to 10 Bar

- Media

- Water, Oil, Chemicals

- Working Temperature

- -10C to 180C

- Port Size

- 1/2 inch to 2 inch

- Surface

- Polished

- Shape

- Round/Body with Ball Float

- Color

- Silver

- Maintenance

- Low Maintenance

- Float Material

- SS316 Stainless Steel Hollow Ball

- Operation

- Fully Mechanical

- Thread Standard

- BSP/BSPT or NPT as required

- Corrosion Resistance

- Excellent (suitable for aggressive environments)

- Mounting Orientation

- Horizontal or Vertical

- End Connection

- Screwed/Threaded Ends

- Leakage Test Pressure

- 1.5 times operating pressure

- Float Ball Diameter

- Available from 40 mm to 100 mm

- Valve Type

- Ball Float Type

ss316 float valves Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-7 Days

About ss316 float valves

Versatile Application Surface and Usage

SS316 float valves feature a robust, polished surface suitable for round-bodied valve assemblies. Designed for easy installation in water tanks, chemical tanks, and across industrial applications, their corrosion-resistant build delivers sustained performance in challenging environments. The float ball operates mechanically, enabling precise fluid control across various media including water, oils, and chemicals. Additional uses cover utility systems, process tanks, and other liquid storage facilities, showcasing the valves adaptability and reliability in routine and specialized operations.

Export Markets, Arrival Estimate, and Sample Policy

Our SS316 float valves are exported worldwide with a prime focus on key markets in Asia, Europe, and the Middle East. The designated FOB port is located in India, ensuring swift international delivery. Arrival rates and time estimates are communicated upon order placement for transparency. We offer samples based on a clear policy, granting clients the chance to evaluate valve performance before committing to large shipments, further enhancing trust and satisfaction across our commercial partnerships.

FAQs of ss316 float valves:

Q: How do SS316 float valves withstand aggressive environments?

A: The SS316 float valves are constructed from high-grade stainless steel, offering excellent corrosion resistance and durability. This makes them highly effective in aggressive environments, such as chemical or industrial applications, where they retain performance and integrity over time.Q: What mounting orientations are supported for these float valves?

A: These float valves can be installed in either horizontal or vertical arrangements, allowing flexibility and adaptability to various tank designs and operational requirements.Q: Where are these SS316 float valves commonly used?

A: Common applications include water and chemical storage tanks, industrial fluid control systems, and oil management units. Their versatility also extends to specialized process tanks in manufacturing and utility facilities.Q: When should maintenance be carried out on these valves?

A: Thanks to their low maintenance design, routine checks and periodic inspections are typically sufficient. Maintenance schedules depend on specific application conditions and media used, enhancing operational longevity and reliability.Q: What is the benefit of choosing a ball float type valve over other valve types?

A: Ball float type valves offer fully mechanical operation, precise control over fluid levels, and reduced maintenance, making them an efficient and dependable choice for automatic tank filling and level regulation.Q: How customizable are the sizes and end connections for these valves?

A: SS316 float valves are available with customizable options, including float ball diameters from 40 mm to 100 mm, port sizes from 1/2 inch to 2 inch, and threaded connections (BSP/BSPT/NPT) to meet your specific system requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Float Valves Category

Stainless Steel 304 float valve

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Float Valve

Material : Other, Stainless Steel 304

Connection : Other, Threaded

Pressure : Other, Up to 10 bar

STAINLESS STEEL FLOAT VALVE ROD

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Float Valve Rod

Material : Stainless Steel

Connection : Other, Threaded or Welded End

Pressure : Other, Upto 10 bar (varies with model)

SS 304 Float Valve

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Float Valve

Material : Stainless Steel

Connection : Thread

Pressure : Specific

Stainless Steel Float Valves

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Stainless Steel

Material : Stainless Steel

Connection : Thread

Pressure : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese